Ensuring Safety for the Oil and Gas Industry

The Oil & Gas industry is essential to the global economy and plays a pivotal role in many industries. However, it inherits dangers that must not be underestimated.

National Disaster Management Authority (NDMA) has reported a staggering 130 documented chemical accidents, resulting in 259 deaths and 563 people with major injuries in the last decade.

Key Challenges

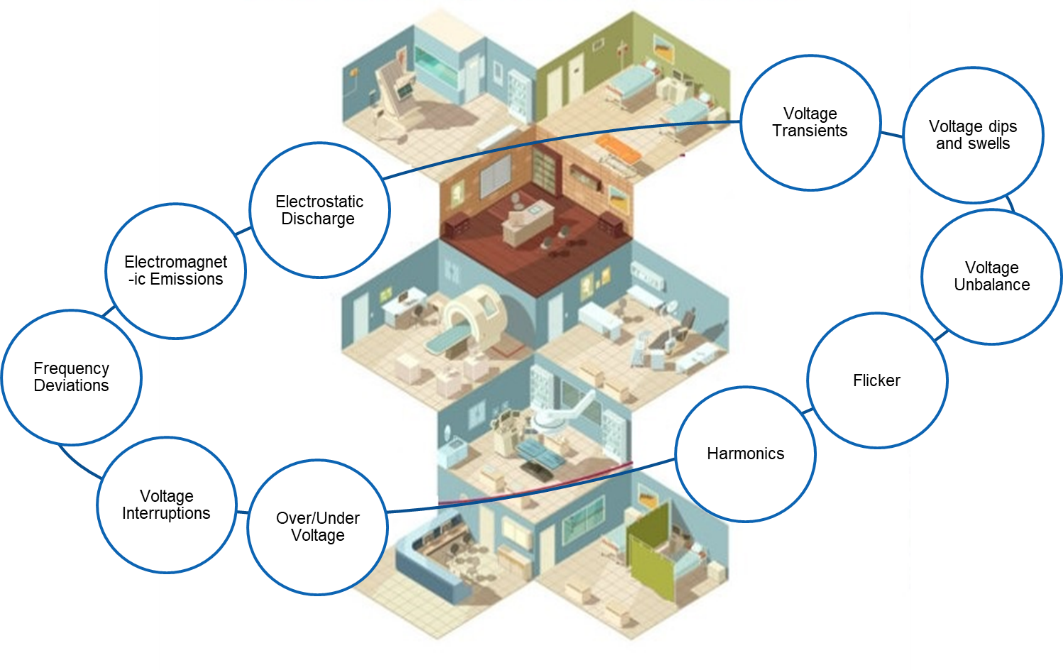

The key challenges in the oil and gas segment range from security system malfunction, equipment malfunction, foundation, and structural failures. The common electrical safety challenges in the oil and gas industry are hazardous environments due to the presence of hazardous flammable gas and liquids...

Lightning strikes are another weather condition that can cause transients and surges that can damage electrical equipment and result in system outages. Electromagnetic Interference can disrupt the proper functioning of electronic and control systems and affect sensitive communication systems, compromising safety measures.

Mitigating such environments and conditions makes the upgrading and maintenance of electrical infrastructure a crucial part of ensuring the safety of the oil and gas segment.

Ensuring Safety Measures

Mitigating safety challenges in the oil and gas industry is an ongoing process and needs a very comprehensive and proactive approach. Staying up with industry regulations and compliance and following the best industry practices is the only way to ensure the safety of people and assets.

- The first and most essential step is education and training of manpower in oil and gas safety management. Employees should be well-trained to identify and respond to such potential risks.

- It is imperative to implement Safety Management Systems (SMS) that identify potential hazards, implement and establish control to mitigate them, and constantly monitor & improve safety measures. Rigorous hazard assessments, including classification of hazardous areas, are essential.

- Constant monitoring of the integrity of assets and equipment. Aging of equipment makes it mandatory to conduct risk assessments on a time-to-time basis in compliance with safety management systems and standard safety regulations.

- A robust design and engineering are mandatory for oil and gas projects. Regular maintenance and installation of proper environmental control system will help in regulating the temperature and humidity.

- Proper grounding and shielding systems will help in mitigating electromagnetic interference, and regular electromagnetic compatibility studies will ensure the early identification of such threats.

- An Effective Lightning Protection System is crucial for protecting personnel and equipment. Regular audits and risk assessments are needed to ensure safety against lightning.

Oil and Gas is a diverse segment and comprises the following sub-industries and segments. Explaining the common challenges faced in each of the industries:

1. Offshore and Onshore Platforms:

These platforms comprise complex extraction and production processes and are exposed to harsh environmental conditions. Robust engineering and implementation of safety protocols are mandatory for ensuring the safety of personnel and reliability of equipment. Similarly, onshore platforms consist of drilling rigs and processing facilities. It is important to follow safety and compliance regulations.

2. Oil and Gas Pipelines:

Electromagnetic Interference can disrupt the operation as they comprise critical electronic systems and equipment. Ensuring the safety and reliability of such systems becomes crucial for uninterrupted operation. Electromagnetic Compatibility (EMI EMC) studies comprising AC/DC interference studies, DC Stray current Analysis, EM Zoning, Matrix & evaluation, shielding, etc., are important for in-depth risk analysis and implementation of mitigation measures.

3. Refineries and Petrochemical Plants:

Major challenges in such industries include meeting stringent environmental regulations, reducing the emission of pollutants, and ensuring electrical safety. Maintenance of complex machinery and equipment is vital to prevent downtime and spurious tripping. Power quality studies and harmonic analysis are crucial studies to mitigate power quality issues and distortions.

Oil and gas industry as a whole comprises complex processes, equipment, and faces a range of challenges. Addressing these challenges requires expertise and technical experience of finding the core issues and then mitigating them. We at JEF techno Solutions offer technical and specialized engineering services for ensuring the safeguard of personnel and improving overall operational efficiency.